PCB Depaneling Machines by Frost

A smart solution!

efficient.

meets high industry standards.

cost-effective.

Only in the absolutely parallel separation method, the separation forces between the tools are clearly transmitted through the core of the remaining web. Thus, tensions in the circuit board and components cannot arise in the first place.

Robust. Versatile. Accident-free.

Stable and robust

Thanks to a sturdy construction and replaceable wear parts, our separation machines are in service for many years.

Universally applicable for...

- all common circuit board materials

- various thicknesses: extremely thin to multilayer

- panels with tall components

- double-sided assembled circuit boards

- all separation lengths from 200 mm to 350 mm

- all standard scoring dimensions

Accident-free

The advantage: Due to the small initial distance and the non-contact separation process, no accidents occur.

And this is how our depaneling machines work

Adjust the distance between the separation tools precisely to the thickness of your circuit board.

Because the scoring serves as a guide, the stop does not need to be adjusted during operation. This allows you to work quickly and smoothly.

No damage to the components and traces is possible during this process.

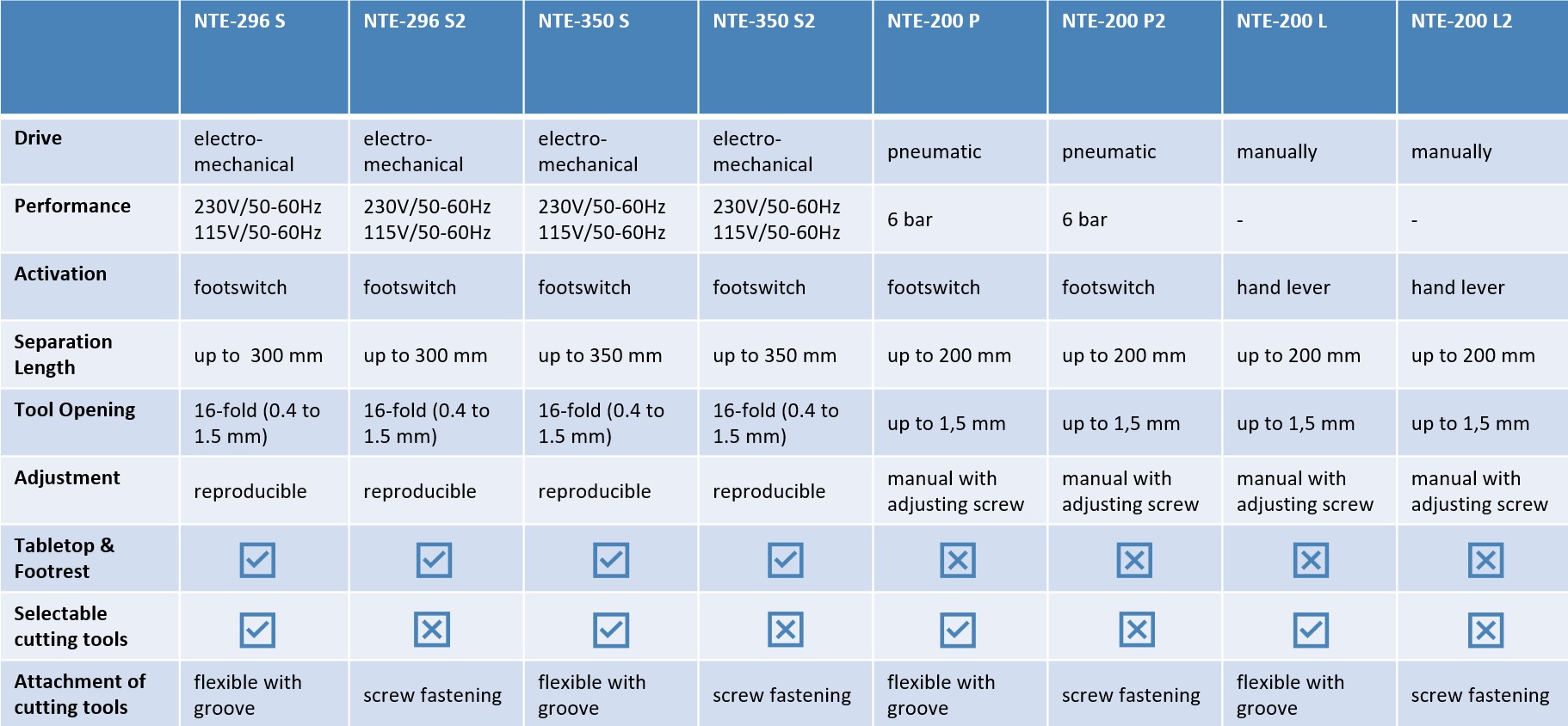

All types at a glance

Our PCB Depaneling Machines in Detail

Electromechanical Precision & Maximum Flexibility up to 300 mm

PCB Depaneling Machine

NTE-296 S

- Drive: electromechanical 230V/50-60Hz 115V/50-60Hz (Footswitch)

- Separation Length: up to 300 mm

- Tool Opening: 16-fold reproducible from 0.4 to 1.5 mm

- Tabletop and Footrest

- Selectable Separation Tools

Electromechanical Precision up to 300 mm

PCB Depaneling Machine

NTE-296 S2

- Drive: electromechanical 230V/50-60Hz 115V/50-60Hz (Footswitch)

- Separation Length: up to 300 mm

- Tool Opening: 16-fold reproducible from 0.4 to 1.5mm

- Tabletop and Footrest

Electromechanical Precision & Maximum Flexibility up to 350 mm

PCB Depaneling Machine

NTE-350 S

- Drive: electromechanical 230V/50-60Hz 115V/50-60Hz (Footswitch)

- Separation Length: up to 350 mm

- Tool Opening: 16-fold reproducible (0.4 to 1.5mm)

- Tabletop and Footrest

- Selectable Separation Tools

Electromechanical Precision up to 350 mm

PCB Depaneling Machine

NTE-350 S2

- Drive: electromechanical 230V/50-60Hz 115V/50-60Hz (Footswitch)

- Separation Length: up to 350 mm

- Tool Opening: 16-fold reproducible, from 0.4 to 1.5 mm

- Tabletop and Footrest

Electromechanical Precision & Maximum Flexibility up to 200 mm

PCB Depaneling Machine

NTE-200 P

- Drive: pneumatic 6 bar (Footswitch)

- Separation Length: up to 200 mm

- Tool Opening: up to 1.5 mm (manual with adjusting screw)

- Selectable Separation Tools

Electromechanical Precision up to 200 mm

PCB Depaneling Machine

NTE-200 P2

- Drive: pneumatic 6 bar (Footswitch)

- Separation Length: up to 200 mm

- Tool Opening: up to 1.5 mm (manual with adjusting screw)

Manual control & Maximum Flexibility up to 200 mm

PCB Depaneling Machine

NTE-200 L

- Drive: manual with hand lever

- Separation Length: up to 200 mm

- Tool Opening: up to 1.5 mm (manual with adjusting screw)

- Selectable Separation Tools

Manual control up to 200 mm

PCB Depaneling Machine

NTE-200 L2

- Drive: manual with hand lever

- Separation Length: up to 200 mm

- Tool Opening: up to 1.5 mm (manual with adjusting screw)

Included in the delivery

NTE-296 S

- EGB-compliant table top

- Grounded footrest with integrated foot switch

- Connection box for grounding wrist strap

- 2 sets of separating tools (optional Form A to E)

NTE-296 S2

- EGB-compliant table top

- Grounded footrest with integrated foot switch

- Connection box for grounding wrist strap

- 2 sets of separating tools (Form A2)

NTE-350 S

- EGB-compliant table top

- Grounded footrest with integrated foot switch

- Connection box for grounding wrist strap

- 2 sets of separating tools (optional Form A to E)

NTE-350 S2

- EGB-compliant table top

- Grounded footrest with integrated foot switch

- Connection box for grounding wrist strap

- 2 sets of separating tools (Form A2)

NTE-200 P

- Tabletop device

- 2 sets of separating tools (optional Form A to E)

- Foot switch

NTE-200 P2

- Tabletop device

- 2 sets of separating tools (Form A2)

- Foot switch

NTE-200 L

- Tabletop device

- 2 sets of separating tools (optional Form A to E)

NTE-200 L2

- Tabletop device

- 2 sets of separating tools (Form A2)

No problem!

We deliver the machine without a table, along with the connection dimensions.

Contact us now and optimize your production reliably and permanently. Even for small quantities.